Windows,Android apps for Engineers/ Students / Educational / Sports / Health personnel etc.

PROCESS

SIMULATION HELP

ProsProsimGraphsPro V8.7

|

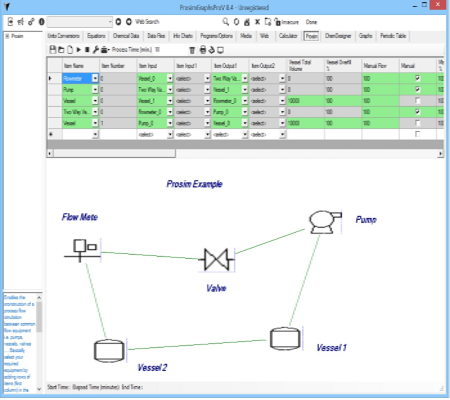

Prosim is a customizable simulation package currently containing 5

process items. These items can be arranged into a multitude of

combinations to simulate many processes. They can even simulate

different process items, all dependant to one’s imagination and

requirements. Each item has it’s own properties that are all accessible via the display grid.

Each items input or output can be affected by adjusting the item

properties.

|

|

Method of Use :

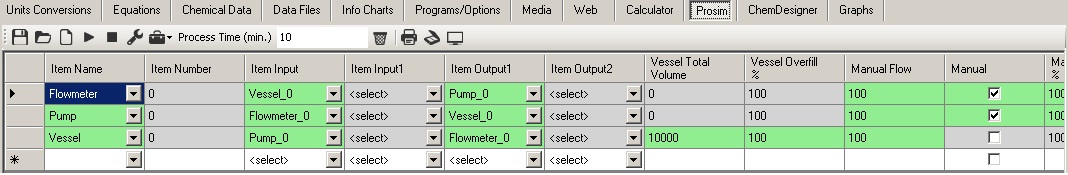

Bascially select your required equipment by adding rows of items (first column) in the grid that will be linked together. The first column contains a droplist of the avaiable process items to select from. The highlight GREEN cells are selectable for that process item. Select each equipments input and output items. Alter each of the equipments flows, timing, valve flow connections. Select the process go button. Green lines indicate flow between equipment. See results by scrolling the grid to the right or using ur mouse hover over the equipment item. Flowmeter is a common starting point, then add the next item that is required. The linking of items is formed by selecting the input or output of the items via the grid.

Menu/Tool Bar Options :

From left to right menu options :-

Save file : Saves the current process design to file.

Open file : Allows for a previously saved file to be opened.

Add item : Adds a new grid item row. Slect the process item from the dropdownlist of the first column. Once an item is selected the rows cells will turn green, which allows the properties of that item that can be changed.

Description of each item :-

Two Way Valves :

Control valves have an input item and also an output item. The

output flowrate of the valve can be control, alter by either

manually, a tank vessel fluid level or by a set time after the

process has started.

Input item : drop down display box :- This is used to select the

input item to the control valve, which represents the incoming flow

to the control valve.

Output item: drop down display box :- This is used to select the

output item from the control valve. This item will receive the output

flow from the control valve. The output item may have a selecting of

select which refers to a zero output.

Tank Level : option button :- Once selected the output of the

control valve will not be affected until the fluid level of the tank

specified is reached. Once the fluid level of the tank is reached the

control valves output will be adjusted according to the percentage

(%) open valve in the open% text box. For instance the output

flowrate will equal input flowrate x the open% valve

Output flowrate = input flowrate x 0.5 hence he output flowrate

will be halved with open% value being equal to 50.

Time : option button :- if this option is set then once the

process has started, after the set time has gone the output flowrate

will be equal to the input flowrate x the open% value. Before this

time is reached the output flow rate equals the input flowrate.

Manually : option button :- if this option is set than the output

flowrate equals the input flowrate x open % value.

FLOWMETERS :

Flowmeters have two inputs one is a set amount of flow from an

external item and the second input is from a defined process item and

also an output item. The output flowrate of the valve can be control,

alter by either manually, a tank vessel fluid level or by a set time

after the process has started.

Input item : drop down display box :- This is used to select the

input item to the Flowmeter, which represents the incoming flow to

the Flowmeter.

Output item: drop down display box :- This is used to select the

output item from the Flowmeter. This item will receive the output

flow from the Flowmeter. The output item may have a selecting of

select which refers to a zero output.

Tank Level : option button :- Once selected the output of the

Flowmeter will not be affected until the fluid level of the tank

specified is reached. Once the fluid level of the tank is reached the

Flowmeters output will be adjusted according to the percentage (%)

open valve in the open% text box. For instance the output flowrate

will equal input flowrate x the open% valve

Output flowrate = input flowrate x 0.5 hence he output flowrate

will be halved with open% value being equal to 50.

Time : option button :- if this option is set then once the

process has started, after the set time has gone the output flowrate

will be equal to the input flowrate x the open% value. Before this

time is reached the output flow rate equals the input flowrate.

Manually : option button :- if this option is set than the output

flowrate equals the input flowrate x open % value.

PUMPS :

Pumps have one input item and an output item. The output flowrate

of the valve can be controlled, alter by either manually, a tank

vessel fluid level or by a control valve

Input item : drop down display box :- This is used to select the

input item to the pump, which represents the incoming flow to the

pump.

Output item: drop down display box :- This is used to select the

output item from the pump. This item will receive the output flow

from the pump. The output item may have a selecting of select which

refers to a zero output.

Tank Level : option button :- The output flowrate of the pump will

vary with the tank level depending if both the high and low settings

are checked or either one is checked. The output flowrate will be set

to the input flowrate x the %open value defined in the text boxes.

Once selected the output of the pump will be affected by the manually

or control valve settings and then affected until the fluid level of

the tank specified is reached.. For instance the output flowrate will

equal input flowrate x the open% valve

Output flowrate = input flowrate x 0.5 hence he output flowrate

will be halved with open% value being equal to 50.

Control Valve : option button :- if this option is set then the

output of the pump is proportional or inversely proportional to the

flowrate of the selected Control Valve. It is proportional to the

valve if the option is set.

Manually : option button :- if this option is set than the output

flowrate equals the input flowrate x open % value.

Three Way Valves VALVES :

Valves have two outputs to two equipment items and one input item.

The output flowrate of the valve can be control, alter by either

manually, a tank vessel fluid level or by a set time after the

process has started. The output flowrate is always geared towards

output number 1, hence if the valve is set manually to 100% then no

flow will go to output number 2, if it is set to 20 % then 20% of the

flow will go to output number 1 and 80 % to output number 2.

Input item : drop down display box :- This is used to select the

input item to the Valve, which represents the incoming flow to the

Valve.

Output item: drop down display box :- This is used to select the

output item from the Valve. This item will receive the output flow

from the Valve. The output item may have a selecting of select which

refers to a zero output.

Tank Level : option button :- Once selected the output of the

Valve will not be affected until the fluid level of the tank

specified is reached. Once the fluid level of the tank is reached the

Valves output will be adjusted according to the percentage (%) open

valve in the open% text box. For instance the output flowrate will

equal input flowrate x the open% valve for output 1 and the rest of

the flow will go to output 2

Time : option button :- if this option is set then once the

process has started, after the set time has gone the output flowrate

will be equal to the input flowrate x the open% value for output 1

and the rest of the flow for output 2. Before this time is reached

the output flow rate equals the input flowrate.

Manually : option button :- if this option is set than the output

flowrate equals the input flowrate x open % value for output 1 and

the rest of the flow for output 2.

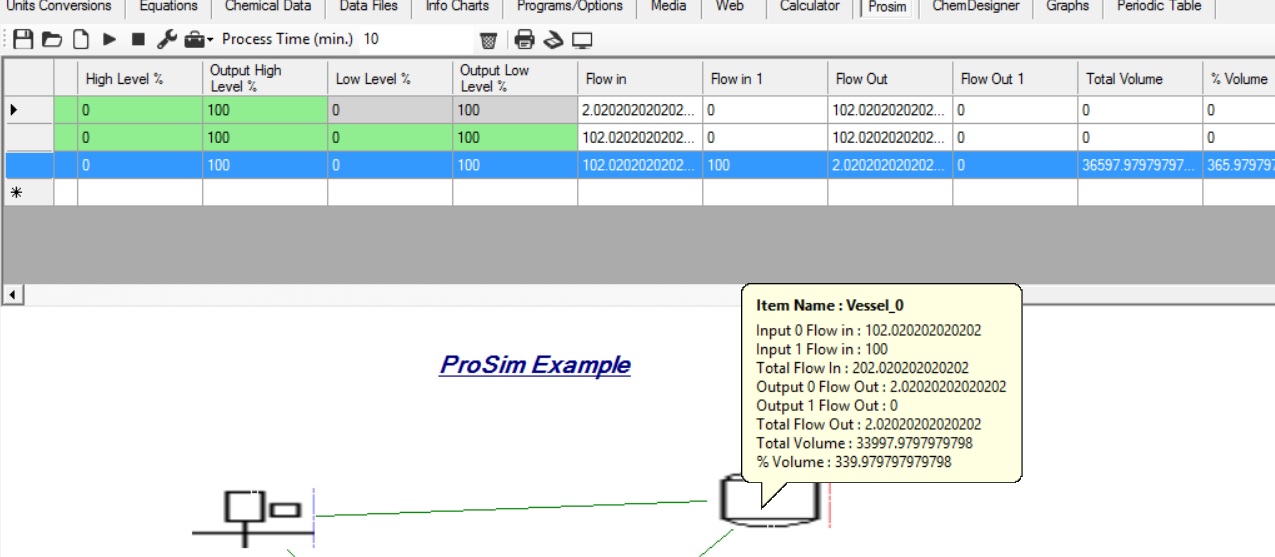

VESSELS :

Vessels have one input item and an output item. The output

flowrate of the vessel is predefined and set in the vessels

properties display.

Input item : drop down display box :- This is used to select the

input item to the vessel, which represents the incoming flow to the

vessel.

Output item: drop down display box :- This is used to select the

output item from the vessel. This item will receive the output flow

from the vessel. The output item may have a selecting of select which

refers to a zero output.

Output Flow : text box: Set the output flowrate of the vessel

Volume : Set the Volume capacity of the Vessel

Vessel Overfill : Set the % overfill of the vessel.

Start Process : Click this option to start the process for the required process time.

Stop Process : Stops the current process.

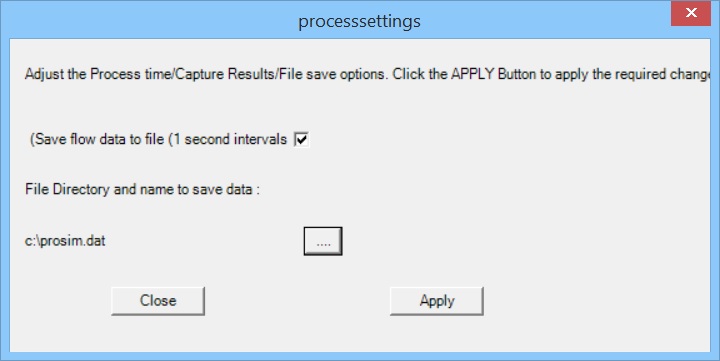

Display Settings : Displays the process settings as below :-

Bascially the processing flows can be saved to a file selected via the file directory button below. Check the "Save Flow data to file" option.

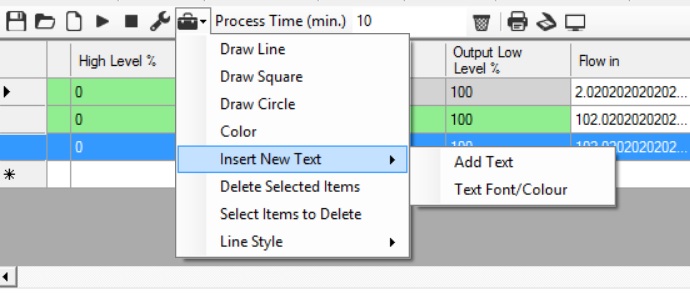

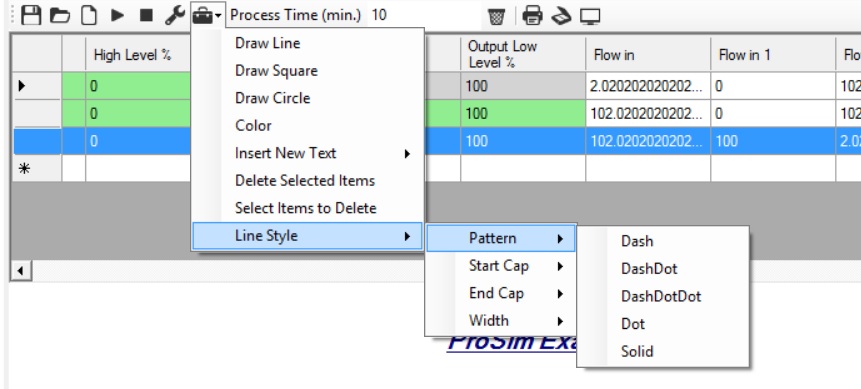

Draw/Tools Options :

From the Toolbox menu allows a dropdown of the graphic items that can be drawn. Mouse Hover over the Color menu options to display a list of selectable colour options. Click on the desired colour.

Draw Line, Square, Circle options. Click on the desired graphic, then mouse click on the prosim form to start the operation. Mouse click again to draw, end the operation.

Mouse Hover over the Color menu options to display a list of selectable colour options. Click on the desired colour.

Insert New Text, allows the insertion of free text, also select the font menu option to set the desired font values.

Select items to Delete : enables a red square to be drawn around the items to be removed. Click the Delete Selected Itmes for the items to be removed.

Line Style : option offers colour, line capping, size options.

Process Time : Enter a value in minutes for the process to run for.

Clear Design : Clears the design/screen.

Print : Prints the scren to the printer.

Print Preview : Prints the screen for a preview.

Remove Selection : Click to remove the selection operation.

A user can press the ESC keyboard key to stop the current operation.